Posts Tagged Furniture

If you’re gonna do it,

Posted by Adam A. Ries in DIY, Furniture on November 3, 2010

DO IT RIGHT!

That is my mantra. I like to see the end results just as much as anyone else, but a hurried project will look hurried. That being said, this is Post 2.5 of a 3 post series of the Roadside Redo cabinet project Click here to read Part 1 in this series, or here to read Part 2.

When this cabinet was originally built, the top wide drawer was made to slide on wooden rails inside the cabinet walls. This is a very simple solution for a drawer slide but by far not the best solution for such a wide, heavy drawer such as this cabinet features. On its original slides the drawer would not have extended from the cabinet very easily; it would have torqued from one side to the other when pulled out or pushed in. Also, once extended more than halfway, the drawer would have begun to fall out of its opening, potentially falling onto the floor (or someones feet) if pulled out all the way. Below is a SketchUp model of what the left cabinet slide looked like originally, highlighted in red.

With all the time I have invested in refinishing this cabinet I wanted a smooth sliding drawer that would operate easily even when weighted down by objects stored inside. For this purpose I purchased drawer slides from my local hardware store. Simple drawer slides come in various lengths; my local hardware store had them in even numbered lengths from 14″ to 24″. My cabinet is just over 17″ deep, so I chose a set of 16″ drawer slides. They came with 2 drawer rails, 2 cabinet rails, all required screws, and detailed instructions (in multiple languages).

Because I had already assembled the cabinet face frame, I would have to make a slight adjustment for the new drawer slides. The instructions call for the drawer opening to be between 1″ and 1 + 1/16″ wider than the drawer width. The width of my drawer was already 38 + 3/4″, and making it narrower would be far too much work. Instead I chose to make notches out of the face frame to allow for the metal drawer slides to operate.

The opening in the cabinet face for the drawer was 39 + 1/16″, and I needed to make it 39 + 3/4″. This meant cutting a 3/8″ notch out of each side of the face frame. Once the drawer is in place, these notches would be practically unnoticeable as they would be hidden by the perimeter of the drawer face. Below is the left of the cabinet opening showing in red where I needed to cut out the notch.

I cut these notches very carefully with a handheld jigsaw, trying to keep them as square as possible; the notches will be noticeable when the drawer is opened and I want them to look very clean. I made the notches just taller than the height of the metal slides. You can see how these notches allow for the metal slides in the photo below.

And in the next photo, the drawer is in! It slides quite well, but is a bit difficult to lift in and out; I don’t plan on removing the drawer very often so it will work fine for me.

Ignore how bright the wood looks in these photos, I was working in a poorly lit garage and the flash seems to think the wood is much lighter and uglier in color than it really is. But you will see that in the Final Reveal in the last post of this series, where I will explain what finish I chose and how to apply it, secure the glass in the doors, and put on all the hardware.

Staining up a Storm

Posted by Adam A. Ries in DIY, Furniture on October 29, 2010

This is post 2 of a 3 part series. Scroll down or simply click here to read post 1 of this series. Expect the final installment in another couple weeks or so. And no, this is not a paid endorsement for Minwax; I just enjoy blogging about high quality products.

Just in time for Halloween, the cuticles around my fingernails look better than those of a real live movie zombie, which can only mean one thing: (no, I’m not preparing for a breakout role in the flick ZombieLand II: Small Town Takeover). I’ve been getting Minwax manicures while applying the stain to my Roadside Redo two door cabinet. As promised, I am going to walk through the entire staining process, but first I want to talk about how I prepared the cabinet for staining.

At the end of the first post of this project I had finished reassembling the cabinet. Before reassembling, I sanded the old varnish off with 60 and then 80 grit sandpaper on my orbital sander. After reassembling I had so many nail holes, brad holes, and seams to fill with wood putty. Because I knew I wanted a dark cabinet, I used a stainable wood filler I have had positive results with in the past.

This is where I have to insert a warning about cheap wood putty; although suitable for painted projects or naturally finished wood, they often don’t absorb dark or even medium stain very well. Just ask the kitchen cabinets I refinished about that.

Using a putty knife I filled all the necessary areas with wood filler and allowed it to dry for several hours, as per the instructions. I first sanded the entire piece with 120 grit and finished with 220 grit sandpaper, leaving the piece exceptionally smooth. Before staining it is crucial to make sure your furniture piece and working area is dust free; getting dust in your stain or finish can be disastrous, leaving a rough surface or imperfections in the finish sheen. I prefer to use a lightly dampened rag to collect the majority of the sanding dust, but always use a tack cloth over the entire furniture piece immediately before applying stain. Now onto the stain I chose.

I knew I wanted a rich, dark brown color; I felt a dark stain would not only look good in the room I intend this piece for, but would help even out the grain pattern and minimize the appearance of knots. From past experience, however, I also knew that a dark stain would be a risky challenge as I am fairly certain this cabinet is yellow pine. Yellow pine does not always accept dark stain well or evenly. I tested every stain I already have from previous projects on the underneath side of the cabinet, but none gave me a deep chocolate color. After a quick trip to my local hardware store, I knew one of the two stain colors I purchased would be the one (but which one…?). Off the Minwax interior wood stain chart, I chose both Jacobean 2750 and Ebony 2718. If Jacobean proved uneven or not dark enough, I would trade deep chocolate for dark chocolate. I ventured to first open only the can I thought would be the most likely successful stain. If I was correct, I would have only opened one and could return the unopened can to the store. Much to my satisfaction, Jacobean proved to be very close to the deep chocolate color I had in mind. No need to even open Ebony (although I am really curious to see how it would have looked, I would rather return it and get my $7.99 back).

Also learned during a previous project, when staining any soft woods (pine, yellow pine, fir, and maple among a few others), it doesn’t hurt to use a pre-stain wood conditioner. Once again I rely on a Minwax product, but I know there are other successful manufacturers. As with any wood filler, stain, varnish, etc, I like to stick with products I have had positive results with in the past. Using the conditioner helps the wood to absorb the stain evenly and prevents dark blotches or streaks from occurring. Just apply it like you would stain, allow to penetrate for 5 – 15 minutes, then wipe off any excess and you’re ready for stain.

For this cabinet I used a clean soft cotton cloth to apply both the conditioner and stain, rubbing the color into the wood but in the direction of the grain. I applied the stain heavily, letting it soak no longer than 5 minutes, then buffed off the excess with another clean absorptive cloth. When completed, the stain was not as dark as I would have hoped in certain spots; I also quickly realized there were more than 1 type of wood in this cabinet as the two side frames stained exceptionally dark (and stand out a bit…hmm). I waited a full 24 hours and reapplied a second coat of stain, letting it soak a few minutes again before wiping off the excess. This darkened and evened out the stain a bit, but as with any furniture piece composed of multiple woods, there will always be color variations that make the piece unique.

Above is a photo of the drawer front as a sneak peek of how the cabinet will look. In the final posts of this series I will elaborate on varnishing the cabinet, fastening the glass into the doors, and securing all the hardware. Hopefully you will read all about that and see the final completed piece soon. Be on the lookout for the Big Finish & Reveal post!

Roadside Redo – The Pickup

Posted by Adam A. Ries in DIY, Furniture on October 20, 2010

This is post 1 of a 3 (+) part series. Expect installment 2 at a later date when this furniture piece is closer to completion.

A few weeks ago, as I was on my Saturday morning drive to a Wedding Show, I spotted 2 things alongside the road that always catch my attention: an abused piece of furniture and a sign that read “FREE.” Actually, it was sitting in the midst of tarp-covered tables at a garage sale as it was quite early and had rained during the night. I stomped on the brakes (safely, looking in my rear view mirror first), and pulled along the road to get a better look. It was a table height cabinet, one drawer across the top and two hinged doors at the bottom. Having been rained on and a in a bit of disrepair (completely falling apart), I got back in my car and drove off. 20 minutes later down the road, I called my sister (waking her up far to early for her Saturday) and asked her to pick it up for me. If there is one thing that adds even more enjoyment to furniture refinishing, it would have to be getting the furniture piece for free. On top of that it would be saving a furniture piece from inevitable death by bonfire or life sentence to a landfill. That same week I began peddling with the piece, completely disassembling it in my garage for a few hours each evening. The cabinet was not built very well, nor was it even very old in age; it was, however, free lumber, already designed, sawn to the right sizes, and a desired piece of furniture that I knew I could find a use for.

(this is where I would insert the before photo. unfortunately, I did not photograph the piece before I began disassembling and sanding it.)

The cabinet is very similar in size and shape to this Better Homes & Garden Entertainment Hutch which sells for over $200 at various home stores and isn’t solid wood (a major criteria for furniture of mine).

After a few weeks of sanding (burning up my orbital sander in the process), I was ready to assemble it this week. Not having to work Thursday, I loaded all the pieces into the mini van (my make-shift pickup) and headed to my Grandfather’s woodworking shop a short drive north from Van Wert. Although someone else built and cut all the lumber for it, with my woodworking background I intended to build it better, stronger, faster.

After a few weeks of sanding (burning up my orbital sander in the process), I was ready to assemble it this week. Not having to work Thursday, I loaded all the pieces into the mini van (my make-shift pickup) and headed to my Grandfather’s woodworking shop a short drive north from Van Wert. Although someone else built and cut all the lumber for it, with my woodworking background I intended to build it better, stronger, faster.

Now for a quick lesson in woodworking joinery. For starters, you don’t attach end grain directly to face grain. It just doesn’t work well. First attempt a dado joint.

A dado wouldn’t have worked for this, it would have made the cabinet slightly narrower and I was afraid the drawer would have rubbed on each side. Second choice? Nailing strip or cleat.

A more noticeable choice, but I wasn’t concerned. After an entire afternoon of trying to put the cabinet back together (make sure to label every piece), I finally have the cabinet reassembled…with my Grandfather’s help.

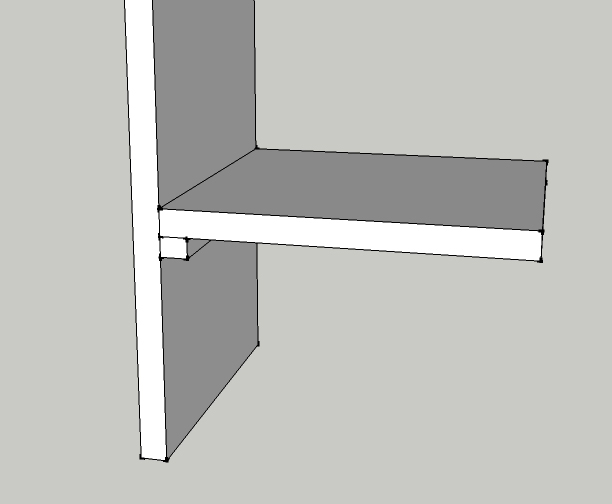

Here is a photo of the bottom shelf, taken from the back. It shows how I attached the bottom shelf to the side wall of the cabinet using a cleat. The cleat is glued and stapled with brads to the side wall, then the shelf is glued and stapled to the cleat and the side wall. Using a cleat here practically triples the glued surface areas.

Between this post and part 2, I will be filling all the nail holes (from the original builder; I used mostly wood glue and clamps and a brad nailer where necessary) with a good stainable wood putty, finish sanding and finding hardware (I really didn’t like the hardware that was on it when I picked it up). You can see from this photograph that this piece has knots everywhere and steep variances in color. I will discuss how I will select a stain color, prepare the cabinet, and finally stain it in the second post of this project. Expect that post in a few weeks, with the final during and after photographs shortly!