Archive for category Home Improvement

The Great Tub Scrub

Posted by Adam A. Ries in DIY, Home Improvement on July 2, 2014

I sit here typing with sore arms, gouges on my index finger, and a lack of fingerprints – they’ve been scrubbed off. All in the name of Nicole Curtis – the famous DIY Network star (aka The Rehab Addict), well known for her love of old character-rich homes and especially vintage plumbing fixtures. Well Nicole, just wait until you see this before & after!

I used her recommendations to bring the homes original old tub (dated 1942 on the base) back into shiny white usefulness. Between rust stains, years of layered silicone adhesive, paint, and old stuck on duct tape, this tub had seen better days. But I knew a beautiful vintage white was hiding underneath.

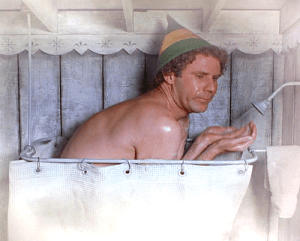

Not quite a luxury soaking tub, eh? Nicole recommends Mr Clean Magic Eraser for light staining and scuffing. For heavy stains and gunk, she claims her secret is Bar Keeper’s Friend.

I used almost an entire canister of Bar Keeper’s Friend (BKF), a nylon scratch pad, utility blade, and sponge. And believe me, it took way longer than the half hour she claims.

The scrubbing takes a lot of elbow grease, and I continuously kept rinsing with hot water so I could see my progress. After about an hour, I had the results below.

It really did clean up pretty good. I already have the over flow & drain assembly put together (it is easier to do this before moving the tub into place), this way as I rinsed each portion the water could just flow down the drain. Unfortunately, the drain area revealed my fears: more than just surface rust. The enameled finish is completely eaten away around the drain flange, showing the rusting cast iron underneath. The area just above the flange, where decades worth of falling water from the faucet hits, is also starting to show the gray metal through the white finish.

These aren’t deal breakers for me. From what I’ve researched, Bondo auto body filler makes the best way to fill the pitted areas where the enamel finish is rusted through. Once dry, it can be sanded smooth with high-grit wetsand paper. Several companies make DIY tub & sink refinishing kits, either brush-on or in an aerosol can, that are supposed to be a durable solution for homeowners to refresh their tubs, just like painting. I’ve read varying reviews on these, but it sounds like if they are applied correctly (thorough scrubbing, etching, and then 2 thin coats) they can last 5-8 years looking just like new. I’m not interested in repainting the entire bathtub, but I’m thinking that is my solution for this small area around the drain.

Another 45 minutes or so of scrubbing tonight, and here is the renewed bathtub! There are a few chips, a few deep rust stains that won’t scrub out, and even a strange yellowy discolored area – but that gives it age and character. New plastic or fiberglass tubs have no place in an old home. They don’t look right, and their hollow sound doesn’t feel right. I want authenticity – the chips, the dings, the scratches and all.

That much closer to a July 4th Holiday Tile Floor & Walls weekend spectacular. The cement board for the shower walls arrives Thursday after work, and then I turn tile pro!

PVC You Later

Posted by Adam A. Ries in DIY, Exterior, Home Improvement on July 1, 2014

As in, I’m done with the PVC drains and vents! What a relief. I had most of the rough plumbing done a few weeks ago, enough to install the subfloor & underlayment, but I still had a few things unfinished. So over the past week I rough plumbed for the tub faucet, shower head, and shower mixer valve.

The extra notch out of the wall stud (don’t worry, this is not a load bearing wall!) is because I second guessed myself about the height of the mixer valve and shower handle. I originally put it at a height that felt comfortable when standing. But then I found that the typical standard is really really low, so I moved it down. After showering just this morning, I realized that as a 6′-4″ man, I don’t want to have to bend down to reach the shower handle. So I think I’m going to move it back up. I did decide upon a very tall height for the shower faucet. I believe it’s time to rid myself of this plague that has troubled my showering experience for the past decade:

Seriously, I can’t even remember what it feels like to wash my hair without ducking or bending half over. I cannot wait.

I also finished the tub drain & overflow – which meant carrying sliding the tub into place – and then I connected all 3 of the bathroom drain vents and ran that vent pipe up through the ceiling. Above are the three vents coming through the floor, connecting to a main vent, and then going up through the ceiling. Once through the ceiling the pip transitions to 2″ in the attic before exiting through the roof. And then bathroom was entirely ready for wallboard!

Based on everything I’ve read, I decided upon cement board on the walls around the tub/shower as a backer board for tile, but the rest of the bathroom walls will be moisture resistant drywall – often called greenboard. My brother-in-law helped me hang a few sheets of drywall Saturday, so the west bathroom wall is covered. I’ll do the same on the east wall. The south wall is staying plaster – with some patching around where the new light switches are. The bathroom is 5’8″ wide, and the tub is only 5′, which leaves me with a narrow space on the wall opposite of the shower head. After some Pinterest searching, I came upon a great solution to use this narrow space- almost the exact size, too.

Not my choice of colors for the towels, but you get the picture. It turns what would otherwise be unusable space into a little bit of storage. It will be fun framing it out, but if I do it right, it might also serve as handy access area to the back of the breaker panel in the wall behind (for future electrical updates needing additional wires).

So to recap, below shows the different stages from just about a month ago to where I am now.

I can almost see the finished product (thanks to the hours I’ve spent on Pinterest!).

I actually got a lot done this week – kitchen sink, tub, part drywall, purchased wall tile for bathroom. But the biggest accomplishment was not mine, but rather what Dennis was able to get connected for me. The process itself is worthy of an entire upcoming post – wet floor, curse words, and a return trip to the hardware store – but for now, I’ll leave it at a single photo and one last sentence. I have hot water.

Floored Once More

Posted by Adam A. Ries in DIY, Home Improvement on June 26, 2014

As the title suggests, this post refers to the next step in finishing the bathroom floor. Because it involved laying down material, I really really wanted to title it “Getting Laid,” but my better judgement stepped in and changed it. Oh well, perhaps a future title.

What I laid was cement board. To achieve the 1-1/4″ total subfloor thickness before I can lay the finish tile floor, I put down 1/2″ cement board over the 3/4″ OSB I installed a few weeks ago (read about that huge step forward over here). The Durock Next Gen brand cement board came in 3′ x 5′ sheets, so it took 4 total to cover the entire floor. I purposely arranged them in a way that they would overlap the joints of the OSB underneath, so not to have seams directly on top of one another. First I dry fit each sheet, cutting them to size and then cutting out the hole for the toilet drain and tub drain access.

While some sources say to simply screw the cement board into place, a professional contractor here in town advised me to set them into mortar thinset, just the same as if I were laying the finish tile floor, and then screw down into place. Why? He said imagine the two layers of subfloor as if they were two regular pieces of lumber. If they are screwed together, the two boards are stronger than they were apart. But if they are laminated together, they are even stronger yet. The same for the cement board and OSB underneath: using mortar thinset “laminates” these two layers together, making the subfloor stronger and less likely to move or flex (which is what causes a tile floor to crack or grout to crack and fail).

I used a trowel to spread the mortar about 1/8 – 1/4 inch thick on the floor, in a square just large enough for one sheet at a time – this is so I wasn’t stepping in the wet mortar. Once I felt I had an even bed of mortar, I used the notched trowel to make ridges and then carefully laid each sheet down, making sure it was pushed flat against the outside wall studs.

I placed screws every 8 or so inches apart, on a grid across each cement board, maybe more along the edges of each board. Unfortunately, the bathroom floor will be about 1/2″ taller than the kitchen floor where they meet. Not ideal in my book, but a custom threshold strip stained to match the wood floor in the kitchen should make a nice transition. So now this floor is ready for tile! Onto the walls.